Failure analysis reports often contain dense terminology, unfamiliar test methods, and highly technical conclusions. For readers without a materials science or semiconductor background, this can make it difficult to extract the most important information—or to know which findings actually matter.

This guide explains how to read a failure analysis report effectively, focusing on what to look for, what questions to ask, and how to interpret conclusions with confidence.

Start With the Objective, Not the Details

Every failure analysis report should begin with a clearly stated objective. Before diving into images or data, identify what the investigation was designed to answer.

Common objectives include:

- Determining root cause of failure

- Assessing authenticity or workmanship concerns

- Evaluating risk to production or field reliability

- Supporting supplier or warranty discussions

Industry guidance from organizations such as NASA stresses that conclusions should always be interpreted in the context of the original investigation objective.

If the objective is unclear, the rest of the report will be harder to interpret accurately.

Pay Attention to the Investigation Scope

Scope defines what was and was not examined. This section is critical for understanding the limits of the conclusions.

Look for statements addressing:

- Sample quantity and selection

- Non-destructive versus destructive techniques used

- Any testing or analysis explicitly excluded

A narrow scope does not invalidate a report—but it does define how far the conclusions can reasonably be extended.

Understand the Difference Between Observations and Conclusions

One of the most important distinctions in any technical report is the difference between observations and interpretation.

- Observations describe what was directly seen or measured

- Conclusions interpret what those observations mean

Standards bodies such as JEDEC emphasize that conclusions should be supported by observable evidence, not assumption

When reading a report, confirm that conclusions clearly reference specific observations rather than general statements.

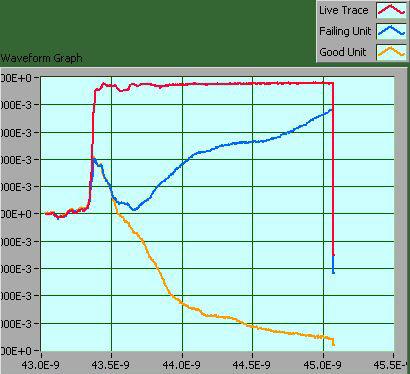

Don’t Get Lost in the Imagery

Failure analysis reports often include microscopy images, cross-sections, or other visuals that can appear overwhelming. While these images are important, the key is understanding why they are included.

Ask:

- What feature is being highlighted?

- How does this image support the stated observation?

- Is the image representative or an isolated example?

If images are not clearly explained in the accompanying text, their relevance may be limited.

Look for Correlation, Not Just Damage

Seeing damage does not automatically explain failure. Strong reports correlate physical evidence with electrical behavior, usage conditions, or known stress mechanisms.

IPC guidance emphasizes correlating material condition with process history and operating environment.

A report that connects what was found to how the part was used or handled is generally more reliable than one that simply documents damage.

Note Any Assumptions or Limitations

Well-written failure analysis reports acknowledge uncertainty. This may include assumptions about operating conditions, incomplete histories, or limited sample size.

Rather than weakening a report, these disclosures strengthen credibility by defining what can—and cannot—be concluded.

If assumptions are not stated explicitly, it is reasonable to ask follow-up questions.

Focus on Risk and Impact

For many readers, the most important part of a failure analysis report is not the technical detail but the practical implication.

Key questions include:

- Is this failure likely to recur?

- Does this affect all parts or only specific conditions?

- What is the risk to production or fielded systems?

A strong report connects technical findings to real-world impact and decision-making.

Asking the Right Follow-Up Questions

If parts of a report are unclear, asking targeted questions can clarify intent and confidence level.

Useful questions include:

- What evidence most strongly supports the conclusion?

- Were alternative failure mechanisms considered and ruled out?

- What additional analysis would increase confidence, if needed?

Failure analysis is often iterative, and clarification is part of the process.

Reading Reports With Confidence

You do not need a materials science degree to read a failure analysis report effectively. By focusing on objectives, scope, evidence, and conclusions—and by understanding how technical observations support decision-making—you can engage with reports confidently and productively.

Clear communication is just as important as technical accuracy in effective failure analysis.

Learn more about our Failure Analysis and Engineering Services to see how findings are documented clearly for technical and non-technical audiences alike.

If you have questions about a failure analysis report or need help interpreting results, contact Priority Labs to discuss your situation.