FAILURE ANALYSIS & ENGINEERING SERVICES

Independent failure analysis, root cause analysis, and materials characterization to support engineering, quality, and reliability decisions.

Clear technical insight. Defensible conclusions. Practical next steps.

Failure

Analysis

Independent investigation of component, assembly, and system failures to identify failure mechanisms and contributing factors.

Engineering Services

Engineering analysis supporting root cause determination, materials characterization, and corrective action development.

Root Cause

Analysis

Structured root cause analysis to determine why failures occurred and define practical, defensible corrective actions.

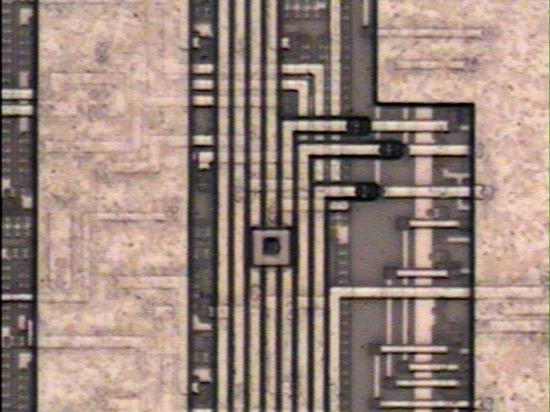

Counterfeit

Analysis

Counterfeit analysis for ICs and electronic components. Verify authenticity with inspection and verification testing, plus documentation to support decisions.

Technical Case Studies & Engineering Analysis

- How to Read a Failure Analysis Report Without a Materials Science BackgroundFailure analysis reports often contain dense terminology, unfamiliar test methods, and highly technical conclusions. For readers without a materials science or semiconductor background, this can make it difficult to extract the most important information—or to know which findings actually matter. This guide explains how to read a failure analysis report effectively, focusing on what to …

- Five Early Indicators That a Failure Is Process-Induced, Not Design-RelatedWhen a component fails, the first instinct is often to question the design. While design flaws do occur, many failures originate earlier or later in the lifecycle—during manufacturing, assembly, handling, or test. Identifying process-induced failures early helps teams avoid misdirected redesign efforts and focus corrective action where it will be most effective. Recognizing these indicators …

- Identifying a Remarked IC in a Suspect Supply Chain LotCounterfeit electronic components remain a persistent risk in modern supply chains, particularly when parts are sourced outside authorized distribution channels. This case study describes how a suspect lot of integrated circuits (ICs) was evaluated to determine authenticity and risk before entering production. The objective was not only to identify whether the parts were counterfeit, but …

Independent. Technical. Defensible.

Our engineers support manufacturers, legal teams, insurers, and consultants with objective analysis grounded in engineering fundamentals and documented evidence.

- Engineer-led investigations

- Clear technical reporting

- Suitable for engineering and legal review

How We Work

- Initial consultation and scope definition

- Technical evaluation and analysis

- Clear findings and recommendations

Need Engineering Insight?

Discuss your technical challenge with an experienced failure analysis team.