Cross-sectioning is a fundamental technique in electronic failure analysis used to expose and evaluate the internal construction of devices and assemblies. By physically sectioning a sample and examining its internal features, engineers can directly observe materials, interfaces, and structures that are otherwise inaccessible. Cross-sectioning plays a critical role in identifying manufacturing defects, material degradation, and failure mechanisms at the component and interconnect level.

Unlike non-destructive methods, cross-sectioning involves permanent material removal. For this reason, it is typically applied after initial screening techniques—such as optical inspection, X-ray imaging, or scanning acoustic microscopy—have identified a region of interest. When executed correctly, cross-sectioning provides definitive physical evidence that supports root cause determination.

Purpose of Cross-Sectioning in Failure Analysis

The primary purpose of cross-sectioning is to reveal the internal construction of a device in a controlled and interpretable manner. This includes exposing features such as:

- Metallization layers and interconnects

- Die attach materials and interfaces

- Solder joints and vias

- Encapsulation and underfill materials

- Layer thicknesses and alignment

By directly observing these features, analysts can assess whether a device was built according to design intent and whether material or process-related defects contributed to failure.

Cross-sectioning is especially valuable when electrical testing or non-destructive inspection indicates a localized problem but cannot fully characterize its physical nature.

Cross-Sectioning Techniques and Preparation

Successful cross-sectioning requires careful sample preparation to avoid introducing artifacts that could obscure or mimic true defects. Preparation typically involves a combination of mechanical and chemical processes, including:

- Precision cutting to isolate the region of interest

- Mounting the sample in epoxy for stability

- Progressive grinding and polishing using controlled abrasives

- Final surface finishing to achieve optical or electron microscopy quality

The choice of preparation technique depends on sample type, materials, and the level of resolution required. Semiconductor devices, printed circuit boards, and molded assemblies each present unique challenges that must be addressed to preserve critical features.

In some cases, selective staining or etching is used to enhance contrast between materials or highlight specific interfaces.

What Cross-Sectioning Can Reveal

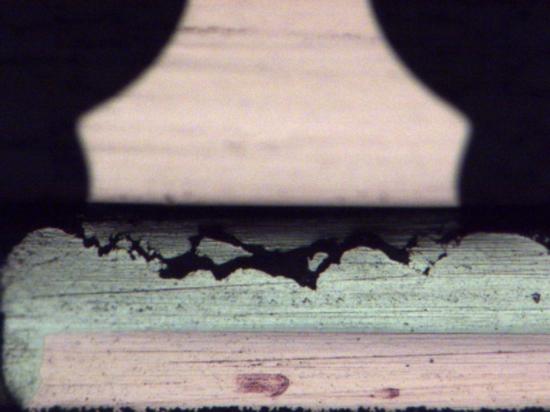

When properly prepared, a cross-section provides detailed insight into failure mechanisms that are difficult or impossible to confirm through other methods. Common findings include:

- Cracked or voided solder joints

- Delamination between materials

- Improper layer thickness or misalignment

- Voids in die attach or underfill

- Corrosion or material degradation

- Manufacturing defects such as incomplete plating or poor adhesion

These observations allow analysts to correlate physical evidence with electrical behavior, environmental exposure, and process history.

Advantages and Limitations

The primary advantage of cross-sectioning is direct physical confirmation. Unlike inferred results from non-destructive techniques, cross-sectioning allows engineers to see and measure the actual condition of internal features. This makes it a powerful tool for validating suspected failure modes and supporting defensible conclusions.

However, cross-sectioning is inherently destructive. Once material is removed, the sample cannot be restored. As a result, careful planning is required to ensure that the correct location is targeted and that sufficient samples are available if multiple analyses are needed.

Additionally, improper preparation can introduce artifacts such as smearing, pull-out, or deformation, which underscores the importance of experienced analysts and controlled preparation methods.

Role of Cross-Sectioning in Root Cause Analysis

Cross-sectioning is most effective when integrated into a broader root cause analysis workflow. Results are often correlated with findings from electrical testing, imaging, and non-destructive inspection to build a complete picture of the failure mechanism.

For example, a delamination detected by scanning acoustic microscopy may be confirmed and characterized through cross-sectioning, while an electrical open localized by time domain reflectometry may be traced to a cracked interconnect revealed in a physical section. This layered approach improves confidence in conclusions and helps eliminate alternative explanations.

By providing tangible physical evidence, cross-sectioning supports clear communication of findings to engineering, manufacturing, and quality teams.

Cross-Sectioning in Practical Failure Investigations

In real-world investigations, cross-sectioning is frequently used to support decisions related to design changes, process improvements, or corrective actions. Measurements obtained from cross-sections can be used for construction analysis, competitor benchmarking, and verification of manufacturing consistency.

At Priority Labs, cross-sectioning is performed using carefully controlled preparation techniques tailored to the specific materials and structures under investigation. When combined with complementary analytical methods, cross-sectioning provides critical insight into internal construction and failure mechanisms in electronic devices and assemblies.