Light-emitting diode (LED) discoloration is a common field concern in electronic assemblies, particularly in applications involving elevated temperature, humidity exposure, or long operating lifetimes. While discoloration is often perceived as a cosmetic issue, it can be indicative of underlying material degradation mechanisms that may ultimately impact optical performance or device reliability.

This case study documents an investigation into localized LED discoloration observed in a fielded electronic assembly. The analysis was conducted to determine the root cause of the discoloration and to identify contributing factors relevant to long-term reliability.

All identifying information related to the product, manufacturer, and application has been removed or generalized.

Background

The device under investigation was a multi-LED assembly used in a field-deployed electronic system. The LEDs were surface-mounted components integrated onto a printed circuit board (PCB) and operated continuously during normal service. The system had been in use for an extended period prior to the onset of visible discoloration.

The discoloration was initially reported during routine inspection and was not associated with immediate functional failure. However, concerns were raised regarding potential performance degradation, long-term reliability, and aesthetic impact.

Failure Symptoms

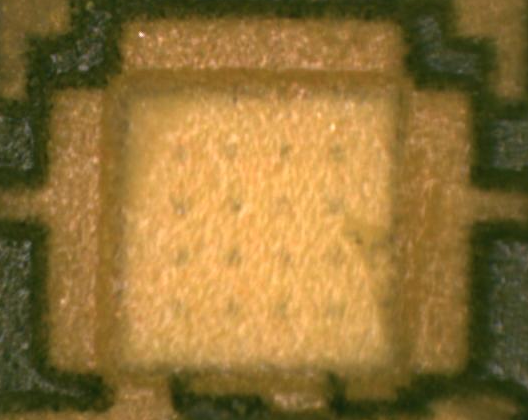

Visual inspection revealed localized yellow-to-brown discoloration affecting the LED package region. The discoloration was not uniform across all LEDs on the assembly and appeared to be more pronounced in specific locations.

Key observations included:

- Discoloration concentrated near the LED encapsulant

- No visible cracking or delamination of the LED package

- No evidence of solder joint damage or PCB charring

- Electrical functionality of the LEDs remained intact at the time of inspection

The non-uniform distribution suggested a localized mechanism rather than a global manufacturing defect.

Analytical Approach

The investigation was designed to identify whether the discoloration originated from:

- LED package materials

- PCB materials or surface finishes

- Environmental exposure

- Electrical or thermal overstress

A phased analytical approach was used to minimize destructive testing while progressively narrowing the region of interest. Techniques were selected to evaluate optical, material, and environmental contributors.

Analytical methods included:

- Optical inspection and documentation

- Comparative analysis between affected and unaffected LEDs

- Materials characterization focused on encapsulant and surrounding structures

- Correlation of discoloration patterns with assembly layout and operating conditions

Findings

Optical inspection confirmed that the discoloration was confined primarily to the LED encapsulant region and did not extend into the solder joints or underlying PCB laminate. The encapsulant material exhibited a noticeable color shift when compared to reference components from unaffected locations.

No evidence of electrical overstress, such as metallization damage or localized overheating of conductors, was observed. Additionally, PCB materials adjacent to the LEDs did not exhibit thermal damage, carbonization, or delamination.

The spatial distribution of the discoloration correlated with areas of the assembly expected to experience higher operating temperatures and reduced airflow. This correlation suggested a thermally accelerated degradation process rather than a random defect.

Material analysis indicated that the discoloration was consistent with polymer aging mechanisms commonly observed in LED encapsulants subjected to prolonged thermal and environmental stress.

Root Cause

The root cause of the observed LED discoloration was determined to be thermally accelerated degradation of the LED encapsulant material. Prolonged exposure to elevated operating temperatures, combined with environmental factors such as humidity, contributed to chemical changes within the encapsulant, resulting in visible color shift over time.

The degradation mechanism was intrinsic to the encapsulant material system and was not attributed to assembly workmanship, PCB materials, or electrical overstress.

Corrective Considerations

While the discoloration did not immediately affect electrical functionality, long-term optical performance and appearance may be impacted as encapsulant degradation progresses.

Potential corrective considerations include:

- Evaluation of alternative LED package materials with improved thermal and environmental stability

- Thermal management improvements to reduce operating temperature at the LED level

- System-level design changes to improve airflow or heat dissipation

- Environmental exposure mitigation in applications with high humidity or temperature cycling

These considerations should be evaluated in the context of application requirements, cost constraints, and expected service life.

Notes on Anonymization

All component identifiers, supplier information, and application-specific details have been removed or generalized to preserve confidentiality. The findings and conclusions presented are based solely on technical observations and analysis.