Counterfeit electronic components remain a persistent risk in modern supply chains, particularly when parts are sourced outside authorized distribution channels. This case study describes how a suspect lot of integrated circuits (ICs) was evaluated to determine authenticity and risk before entering production.

The objective was not only to identify whether the parts were counterfeit, but to document evidence in a way that supported sourcing decisions and potential supplier discussions.

Background and Initial Concern

A customer submitted a small lot of ICs after inconsistencies were noticed during incoming inspection. While the parts passed basic electrical screening, visual differences raised concerns regarding authenticity.

The customer’s primary questions were:

- Are these devices genuine?

- If not, what indicators support that conclusion?

- What is the risk of using these parts in production?

Because sample quantity was limited, a structured, evidence-preserving analysis plan was required.

Step 1: External Visual and Marking Inspection

The investigation began with non-destructive visual inspection under magnification. Several inconsistencies were observed when compared to known-good reference images and manufacturer documentation.

Observed indicators included:

- Inconsistent font alignment and character depth

- Surface texture variations inconsistent with expected mold compound finish

- Evidence of surface abrasion beneath top-side markings

Industry guidance such as IDEA-STD-1010 emphasizes that remarking and resurfacing often leave subtle but detectable physical signatures.

At this stage, the devices were classified as suspect, but not yet confirmed counterfeit.

Step 2: Dimensional and Package Consistency Checks

Dimensional measurements and package outline comparisons were performed next. While overall package size was within tolerance, lead geometry and finish showed variation inconsistent with the manufacturer’s published package drawings.

JEDEC package standards provide baseline expectations for package construction and dimensional consistency.

The variation suggested either non-standard manufacturing or post-manufacturing alteration.

Step 3: Electrical Screening (Controlled)

Basic electrical tests were performed to avoid altering potential physical evidence. The devices functioned within expected limits under nominal conditions.

This result reinforced a common counterfeit scenario: remarked or refurbished devices that remain electrically functional, at least initially. Electrical pass results alone were insufficient to clear the lot.

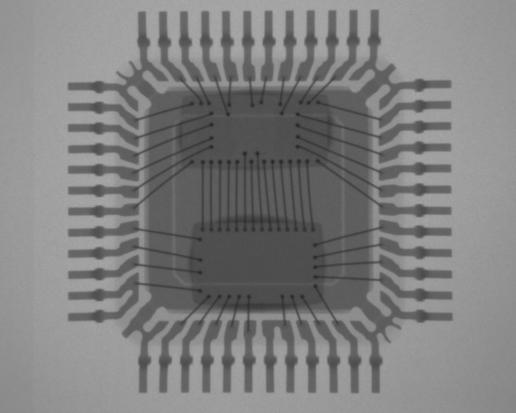

Step 4: Targeted Physical Verification

Based on the visual and dimensional findings, targeted physical verification was performed on a subset of samples. Internal construction features were evaluated and compared against expected characteristics for the device family.

Discrepancies were identified between internal features and publicly available construction references. These differences were inconsistent with known manufacturer processes and supported a conclusion of remarking and reintroduction into the supply chain.

ASM and IPC references note that reclaimed or refurbished parts often retain internal evidence even when external appearance has been altered.

Findings and Conclusion

The combined evidence supported the conclusion that the submitted devices were remarked components, likely reclaimed and reintroduced into the supply chain as new.

Key indicators included:

- Surface modification consistent with resurfacing

- Non-standard marking characteristics

- Package and internal inconsistencies relative to expected construction

While the devices were electrically functional at the time of testing, the authenticity risk and unknown prior usage history presented unacceptable reliability concerns.

Outcome and Customer Impact

The documented findings allowed the customer to:

- Reject the suspect lot before production use

- Engage the supplier with objective, defensible evidence

- Strengthen incoming inspection criteria for future purchases

Early identification prevented potential downstream failures, warranty exposure, and qualification delays.

Lessons Learned

This case highlights several important points:

- Electrical testing alone cannot confirm authenticity

- Physical evidence often provides the strongest indicators of counterfeit activity

- Structured analysis preserves evidence and improves decision confidence

Counterfeit analysis is most effective when visual, dimensional, electrical, and physical findings are evaluated together.

Learn more about our Counterfeit Analysis and Failure Analysis services to see how similar investigations are conducted.

If you have concerns about suspect components or supply chain risk, contact Priority Labs to discuss your analysis needs.