Scanning Acoustic Microscopy

Scanning Acoustic Microscopy (SAM) is a non-destructive imaging technique that uses focused ultrasonic energy to examine the internal features of materials and assemblies. The technique is particularly well suited for detecting subsurface defects and interfaces in electronic components, semiconductor packages, and layered structures where visual inspection is not possible. At Priority Labs, SAM is used to evaluate a wide range of samples as part of failure analysis, quality investigations, and construction analysis.

SAM operates by directing focused sound from an ultrasonic transducer toward a small point on the target object. When the acoustic wave encounters the material, portions of the sound energy may be scattered, absorbed, reflected, or transmitted depending on the acoustic impedance differences between materials and interfaces. Reflected sound—often referred to as backscattered energy—returns toward the transducer and is detected to provide information about internal boundaries or inhomogeneities. General background on ultrasonic testing principles is available through the American Society for Nondestructive Testing (ASNT).

A key parameter in SAM analysis is the time of flight of the acoustic pulse. Time of flight is defined as the time required for the sound pulse to be emitted by the transducer, interact with an internal feature, and return to the detector, which is typically coincident with the source. By knowing the speed of sound in the coupling medium and sample material, the time-of-flight measurement can be converted into a depth location. This allows internal features to be mapped spatially without physically sectioning the sample.

Imaging Process and Data Interpretation

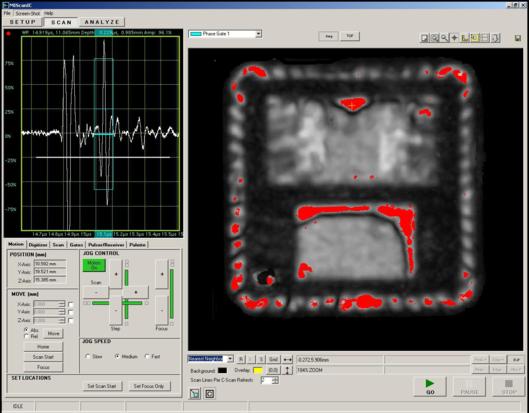

During a SAM inspection, a focused acoustic beam is directed at a specific location on the sample surface. Based on the detected response, a numerical value is assigned to that location, representing the strength or timing of the reflected signal. The transducer or sample is then moved incrementally, and the process is repeated in a systematic scanning pattern until the entire region of interest has been examined.

The collected data points are assembled into an image representing the internal structure of the object. Image contrast is generated by differences in acoustic response, which are influenced by material composition, geometry, and the presence of interfaces or defects. Features such as delamination, voids, cracks, and poor adhesion produce distinct acoustic signatures due to impedance mismatches between adjacent materials.

Resolution in SAM imaging is governed by both the mechanical scanning resolution and the width of the acoustic beam. Beam width, in turn, is determined primarily by the frequency of the ultrasonic signal, with higher frequencies providing finer resolution at the expense of reduced penetration depth. A technical overview of resolution tradeoffs in acoustic microscopy can be found through Olympus IMS.

Advanced Technical Considerations

At Priority Labs, SAM analysis is performed using a Matec Micro-Electronics Scanning Acoustic Microscope, enabling both reflected-mode and through-transmission scans. Reflected scans are used to detect interfaces and defects within the sample by analyzing sound reflected back to the transducer, while through scans detect sound transmitted through the sample and received by a separate transducer on the opposite side. Each scan mode provides different information and is selected based on sample construction and investigative goals.

Priority Labs performs SAM inspections at transducer frequencies of 15 MHz, 75 MHz, and 100 MHz, allowing flexibility in balancing penetration depth and spatial resolution. Lower frequencies are useful for thicker samples or deeper features, while higher frequencies provide enhanced resolution for detecting small defects near the surface or within thin layers. Selection of transducer frequency is a critical aspect of SAM analysis and is tailored to the specific sample and defect types under investigation.

SAM is especially effective for examining semiconductor packages, including molded devices, BGAs, and multi-chip modules, where internal delamination or voiding can lead to reliability issues. It is also widely used for evaluating adhesion quality between layers, detecting moisture-induced damage, and identifying manufacturing anomalies that may not be evident through electrical testing alone. Additional application examples for SAM in electronics can be found through Sonoscan / Nordson, a leading supplier of acoustic microscopy systems.

Because SAM is non-destructive, it is frequently used early in an investigation to identify areas of interest before applying destructive techniques such as cross-sectioning or focused ion beam (FIB) analysis. SAM results can guide subsequent analytical steps by narrowing the region of interest and reducing unnecessary material removal. When combined with X-ray inspection, electrical testing, or physical analysis, SAM contributes to a more efficient and targeted investigative workflow.

At Priority Labs, SAM data is interpreted by experienced analysts who understand both the capabilities and limitations of the technique. Care is taken to distinguish true defects from benign interfaces or acoustic artifacts. Results are integrated with other analytical findings to develop a comprehensive understanding of sample condition and potential failure mechanisms.

Through the use of advanced acoustic microscopy equipment and disciplined analytical workflows, Priority Labs provides SAM services that support reliable detection of internal defects while preserving sample integrity. Scanning Acoustic Microscopy remains a critical tool for non-destructive evaluation of complex electronic assemblies and layered materials.

Related Services: