IC FAILURE ANALYSIS SERVICES

Priority Labs provides independent failure analysis services to identify failure mechanisms, root causes, and contributing factors in electronic, semiconductor, and advanced technology products.

Objective analysis. Defensible conclusions.

What Is Failure Analysis?

Failure analysis is the systematic investigation of why a product, component, or system did not perform as intended. This process combines inspection, testing, and analytical techniques to determine the underlying cause of failure.

Our analyses are conducted independently and documented clearly to support engineering decisions, quality improvements, and legal or insurance matters.

Failure Analysis Capabilities

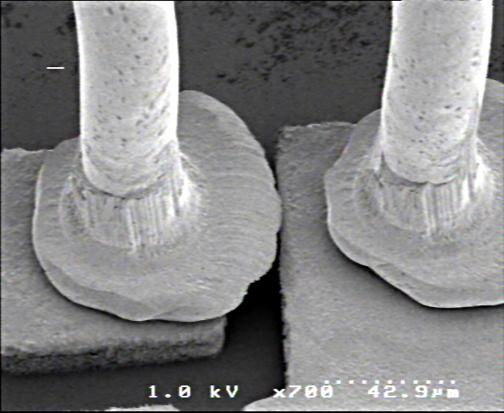

Mechanical Failure Analysis

Investigation of fractures, fatigue, wear, overload, and manufacturing-related mechanical failures in components and assemblies.

Electrical & Electronics Failure Analysis

Failure analysis of electronic components, PCBs, assemblies, and electrical systems affected by overstress, defects, or environmental exposure.

Materials Failure Analysis

Evaluation of metals, polymers, ceramics, and composites for defects, degradation, improper processing, or specification non-compliance.

Our Failure Analysis Process

- Initial consultation and background review

- Non-destructive inspection and screening

- Targeted destructive analysis (when required)

- Root cause determination

- Clear documentation and technical reporting

Who We Support

- Manufacturers and product design teams

- Quality, reliability, and supplier engineering groups

- Legal counsel and insurance professionals

- Consultants and failure investigation teams