Cross-sectioning

Cross-sectioning is a fundamental analytical technique used to expose and examine the internal structure of components, materials, and assemblies. At Priority Labs, cross-sectioning is performed across a wide range of sample types, including semiconductor devices, injection-molded plastics, printed circuit board (PCB) assemblies, and complex multi-material systems. This technique allows internal features that are otherwise hidden to be directly observed, measured, and evaluated.

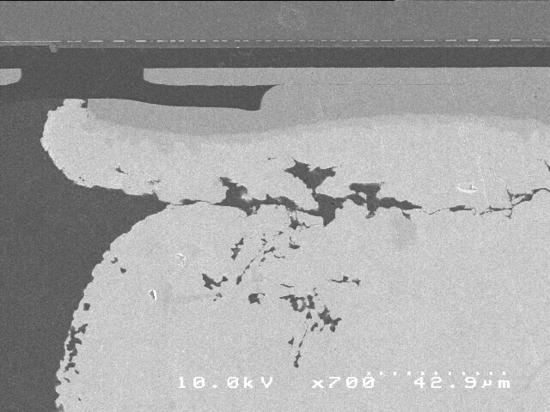

By physically cutting, mounting, polishing, and preparing a sample to reveal a specific plane of interest, cross-sectioning enables detailed inspection of layers, interfaces, and construction features. It is commonly used to investigate manufacturing defects, assess material quality, verify construction details, and support failure analysis and root cause investigations. Unlike non-destructive techniques that infer internal conditions indirectly, cross-sectioning provides direct visual and dimensional evidence of how a part was built and how it may have failed.

Cross-sectioning is particularly valuable when questions arise regarding material thickness, layer uniformity, bonding quality, voiding, cracking, or alignment. In PCB assemblies, for example, cross-sections can reveal solder joint integrity, via fill quality, plating thickness, and internal trace construction. In molded plastics and composite materials, cross-sectioning can expose fiber distribution, voids, weld lines, and other features that influence mechanical performance and reliability.

Because cross-sectioning is inherently destructive, careful planning is essential. Priority Labs works closely with customers to define the region of interest and ensure that sectioning is performed in a manner that preserves critical evidence and supports the overall investigation. When performed correctly, cross-sectioning provides highly reliable information that forms the foundation for clear, defensible engineering conclusions.

Advanced Technical Discussion

From a technical standpoint, effective cross-sectioning requires a combination of precise sample preparation, material-specific techniques, and experienced interpretation. Different materials respond very differently to cutting, grinding, and polishing processes, and improper preparation can introduce artifacts that obscure or distort the true condition of the sample. Priority Labs’ analysts and engineers have developed specialized cross-sectioning methods tailored to a wide range of materials and constructions.

For semiconductor devices, cross-sectioning may involve exposing die structures, interconnect layers, passivation coatings, and packaging features. Achieving clean, artifact-free sections at these scales often requires fine control over sectioning orientation, polishing pressure, and abrasive selection. For PCB assemblies, cross-sectioning is used to evaluate internal copper layers, plated through-holes, microvias, solder joints, and laminate structures. Accurate alignment is critical to ensure that the section intersects the intended features and provides meaningful measurements.

Injection-molded plastics and composite materials present their own challenges, including smearing, pull-out, and deformation during preparation. Priority Labs employs specialized mounting techniques and delineation stains to enhance contrast between materials, phases, or features. These stains can highlight interfaces, reveal microcracking, and differentiate between similar materials, improving the clarity and interpretability of the final cross-section.

Measurement is a key component of cross-section analysis. Priority Labs utilizes a range of calibrated measurement tools to quantify feature dimensions such as layer thickness, plating depth, bond line width, and material distribution. These measurements support construction analysis, competitor benchmarking, and verification against design or specification requirements. In many cases, quantitative cross-section data is essential for identifying subtle process variations or deviations that contribute to performance issues or failures.

Cross-sectioning is frequently used in conjunction with other analytical techniques. For example, non-destructive methods such as X-ray imaging or acoustic microscopy may be used to identify areas of interest before sectioning, while optical microscopy or scanning electron microscopy (SEM) may be applied after sectioning to further examine exposed features at higher magnification. This integrated approach ensures that destructive analysis is targeted, efficient, and maximally informative.

At Priority Labs, cross-sectioning plays a critical role in broader failure analysis and root cause determination efforts. The technique provides direct physical evidence that supports or refutes hypotheses generated through electrical testing, modeling, or non-destructive inspection. When combined with experienced engineering judgment, cross-sectioning results help clarify failure mechanisms, identify contributing factors, and guide corrective action development.

Through careful planning, advanced preparation techniques, and rigorous interpretation, Priority Labs delivers cross-section analysis that supports reliable conclusions and informed decision-making. Whether used for failure investigation, quality assessment, or competitive construction analysis, cross-sectioning remains an essential tool for understanding how materials and assemblies are built—and how they perform in real-world applications.

Related Services: