Failure analysis often begins with urgency: a failed part, a missed shipment, or pressure to identify fault quickly. In that environment, it’s tempting to move directly into testing or teardown. However, starting without a defined analysis plan frequently leads to wasted samples, inconclusive results, or misleading conclusions.

A well-designed failure analysis plan aligns objectives, techniques, and constraints before the hardware is altered—preserving evidence and improving outcome quality.

Why Planning Matters in Failure Analysis

Every analysis decision has consequences. Electrical stress can exacerbate existing damage, while physical disassembly may eliminate critical behavioral evidence. Guidance from organizations such as NASA emphasizes that premature testing can mask the original failure mechanism rather than reveal it

(see NASA’s Failure Analysis Process overview).

Effective planning ensures that each step builds toward a defensible conclusion rather than reacting to incomplete observations.

Define the Objective First

Before selecting tools or techniques, the investigation objective must be clear. Different goals require different approaches.

Common objectives include:

- Determining root cause of a functional failure

- Screening suspect parts for authenticity or workmanship concerns

- Supporting supplier discussions or disputes

- Assessing risk to production or fielded systems

Industry standards bodies such as JEDEC stress that failure analysis methods should be selected based on the investigation goal, not simply on tool availability.

An investigation aimed at screening is fundamentally different from one intended to establish root cause. Treating them the same often leads to frustration and rework.

Understand the Constraints

Failure analysis is rarely performed under ideal conditions. Constraints should be identified early and revisited throughout the investigation.

Key constraints often include:

- Limited sample quantity

- Time sensitivity or production pressure

- Cost or schedule limitations

- Documentation or traceability gaps

Standards such as IPC-TM-650 acknowledge these real-world constraints and emphasize adapting analysis depth accordingly.

Recognizing limitations upfront allows the analysis plan to prioritize information gain while minimizing irreversible actions.

Sequence Matters: Non-Destructive Before Destructive

Whenever possible, non-destructive techniques should be applied before destructive ones. This preserves original device behavior and maximizes available evidence.

A typical progression may include:

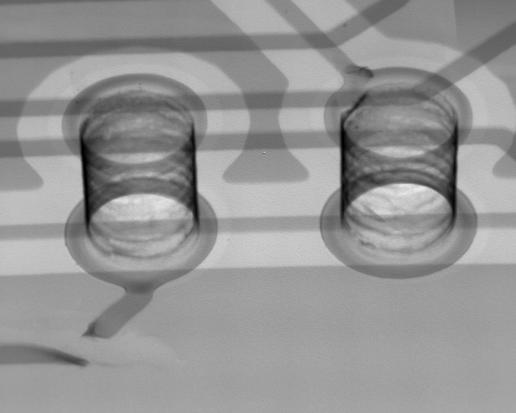

- Visual and external inspection

- Electrical screening under controlled conditions

- Targeted physical analysis based on observed evidence

JEDEC and IPC guidance consistently recommend non-destructive evaluation as an initial step when sample quantity is limited or failure mechanisms are uncertain.

Skipping directly to destructive analysis can eliminate opportunities to correlate electrical behavior with physical findings.

Avoid “Fishing Expeditions”

One of the most common failure analysis pitfalls is performing tests simply because they are available. Each technique should serve a defined purpose within the investigation.

Questions to ask before each step:

- What decision will this result inform?

- What evidence might be lost by proceeding?

- Is this technique justified by existing observations?

NASA and aerospace failure analysis programs routinely highlight that exploratory testing without a hypothesis often increases cost without improving clarity.

Purpose-driven analysis is faster, more efficient, and far more defensible than exploratory testing without direction.

Document the Plan — and the Deviations

Even a well-designed plan may evolve as new information emerges. What matters is documenting both the original plan and the rationale for any deviations.

Clear documentation:

- Preserves investigation credibility

- Supports internal reviews and supplier discussions

- Enables repeatability for future analyses

Well-documented reasoning often matters as much as the final conclusion, particularly in regulated or contractual environments.

Planning Leads to Better Outcomes

An effective failure analysis plan does not slow the investigation—it accelerates it by preventing missteps and preserving evidence. By defining objectives, understanding constraints, sequencing techniques thoughtfully, and documenting decisions, investigations become more efficient and more reliable.

Failure analysis is not just about tools. It is about applying the right tools, in the right order, for the right reasons.

Learn more about our Failure Analysis and Engineering Services to see how structured investigation planning supports accurate and defensible results.

If you need help defining an investigation plan or determining the appropriate analysis path, contact Priority Labs to discuss your specific needs.