Counterfeit Analysis

Avoid production delays, warranty risk, and safety issues from counterfeit ICs and electronic components. We evaluate suspect parts and provide clear documentation so you can make a confident go/no-go decision.

Priority Labs provides independent counterfeit analysis services to determine whether integrated circuits (ICs) and electronic components are genuine, remarked, refurbished, or otherwise suspect. Our approach combines non-destructive screening and targeted physical/electrical verification to support confident sourcing and quality decisions.

What Is Counterfeit Analysis?

Counterfeit analysis is the systematic evaluation of electronic parts to identify authenticity risks such as remarking, resurfacing, die substitution, reclaimed/refurbished components sold as new, or parts that do not meet manufacturer specifications. The goal is a clear, evidence-based determination you can use to prevent escapes into production and reduce reliability, warranty, and safety risk.

Our investigations are conducted independently and documented clearly to support supplier decisions, quality controls, reliability programs, and (when needed) defensible records for disputes or compliance.

Counterfeit Analysis Capabilities

Non-Destructive Screening

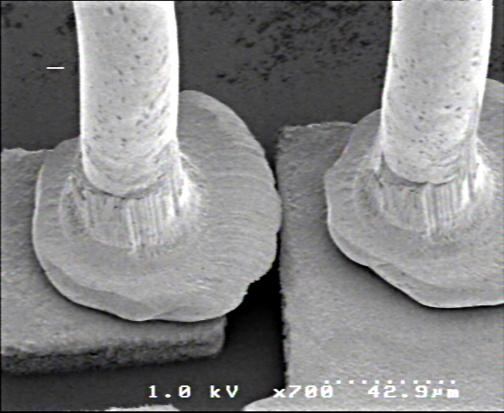

Initial screening methods help identify red flags without altering the part. This may include external visual inspection, marking and label review, dimensional checks, and imaging techniques used to spot inconsistencies from expected construction.

Packaging & Construction Verification

When higher confidence is required, we verify packaging and internal construction using appropriate techniques for the device type. This can include evaluation of surface condition, lead finish condition, mold compound indicators, and internal structure consistent with authentic manufacturing.

Electrical Verification (As Applicable)

Where feasible, electrical checks can help confirm whether the device behaves consistently with the expected part family and revision. Testing approach depends on package type, available documentation, and your program needs (incoming inspection vs failure investigation vs dispute resolution).

Our Counterfeit Analysis Process

- Initial consultation and part background review (source, lot size, traceability, concerns)

- Non-destructive inspection and screening

- Targeted deeper verification (only when required)

- Authenticity risk assessment and findings

- Clear documentation, photo evidence, and reporting

Who We Support

- OEMs and product design teams

- Quality, reliability, and supplier engineering groups

- Contract manufacturers and EMS providers

- Distributors and procurement teams managing high-risk sourcing

- Legal counsel and organizations requiring documentation for disputes (when applicable)