When investigating a suspect integrated circuit (IC), one of the first questions engineers face is whether to begin with electrical testing or physical analysis. Choosing the wrong starting point can waste time, consume limited samples, or obscure the true failure mechanism.

Understanding the strengths and limitations of each approach helps ensure the investigation produces clear, defensible conclusions.

Electrical Testing: Strengths and Limitations

Electrical testing evaluates how a device behaves under defined operating conditions. This can range from simple continuity or parametric checks to more detailed functional or stress testing, depending on the part type and available documentation.

Electrical results are often the fastest way to determine whether a device is functionally suspect, but they rarely explain why a failure occurred.

Electrical testing is most effective when:

- The device exhibits intermittent or outright functional failure

- Specifications or known-good comparison data are available

- Non-destructive screening is required

- Large quantities of parts need rapid triage

However, electrical testing alone may miss underlying issues such as internal damage, contamination, or manufacturing anomalies that have not yet progressed to a functional failure.

Physical Analysis: Strengths and Limitations

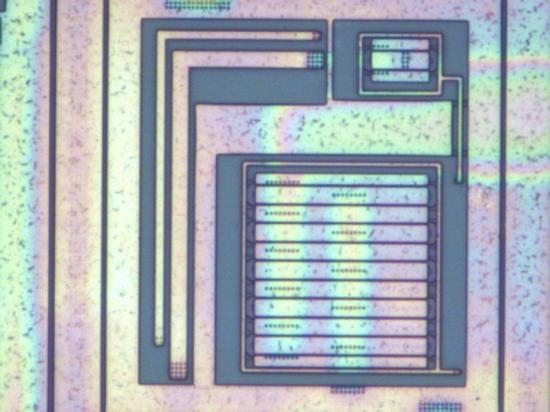

Physical analysis focuses on the construction and condition of the device itself. Techniques range from external visual inspection to more detailed internal evaluation methods, depending on the investigation goals and sample availability.

Physical analysis is particularly valuable when failures are latent, structural, or process-induced, or when counterfeit or workmanship concerns are present.

Physical analysis is most effective when:

- Electrical symptoms are inconsistent or unexplained

- Counterfeit, remarking, or refurbishment is suspected

- Process-related damage is suspected

- Documentation or traceability is limited

The tradeoff is that physical analysis often requires greater planning. Some techniques may be destructive, meaning the investigation path must be carefully defined before analysis begins.

Why the Starting Point Matters

Beginning with the wrong method can unintentionally compromise the investigation. For example, aggressive electrical stressing can worsen existing damage, while premature physical analysis may eliminate the opportunity to observe original failure behavior.

A successful investigation typically balances information gained versus information lost at each step.

In many cases, a combined approach—starting with controlled electrical screening followed by targeted physical analysis—produces the most reliable results.

A Practical Decision Framework

- Define the question first

Is the goal to confirm functionality, determine root cause, screen incoming parts, or support a supplier dispute? - Assess sample availability

Limited samples favor non-destructive electrical testing early. - Evaluate risk of alteration

Some tests can permanently alter the device and should be deferred. - Plan the full investigation path

Decisions should support downstream analysis, not block it. - Escalate only when justified

Deeper physical analysis should be driven by evidence, not assumption.

Applying the Right Tool at the Right Time

Electrical testing and physical analysis are not competing approaches—they are complementary tools. The key is applying them in the proper sequence to answer the right questions without compromising evidence.

Careful upfront planning ensures the investigation remains efficient, objective, and technically defensible.

Learn more about our Failure Analysis and Engineering Services to see how these techniques are applied in real investigations.

If you’re unsure how to structure an investigation or which techniques are appropriate for your situation, contact Priority Labs to discuss your analysis needs.